How to Cut Acrylic Sheets Safely and Accurately: DIY Tips for 2025

Posted by My Charity Boxes Team on 10th Jul 2025

Introduction

Acrylic sheets are widely used in everything from donation boxes to signage, displays, and retail fixtures. They’re lightweight, durable, and beautifully transparent—making them perfect for DIY acrylic donation boxes and other creative projects.

But there’s one catch: cutting acrylic requires precision and care. One wrong move and you risk cracks, uneven edges, or melted corners.

Whether you’re a first-time DIYer or a charity organizer building a custom donation solution, this guide explains how to cut acrylic sheets safely and accurately. You'll learn which tools to use, the best techniques for different thicknesses, and how to get professional-looking results.

Prefer a ready-made box with lockable features and a flawless finish?

Browse our acrylic donation box collection for professionally crafted solutions.

Choosing the Right Acrylic Sheet

Before you even pick up a blade, it's essential to understand the material you’re working with. Not all acrylic is the same, and the thickness and type of sheet will determine the right cutting method.

Common Acrylic Thicknesses and Their Uses

- 1/8" (3mm): Lightweight and flexible. Ideal for small projects like display signs or basic box panels. Easily cut with a scoring knife.

- 3/16" (4.5mm): Offers added rigidity and strength. Suitable for mid-size donation boxes or enclosures. May require a jigsaw for clean results.

- 1/4" (6mm): Thick, highly durable, and heavy-duty. Used for larger installations or outdoor projects. Best cut using a circular saw or laser.

Types of Acrylic Sheets

- Clear Acrylic: Most popular for charity boxes. Offers maximum transparency and donor visibility.

- Tinted Acrylic: Great for branding or creating mood. Slightly harder to cut due to color pigments.

- Printed or Frosted Acrylic: Often used for signage. May require slower, more delicate cuts to preserve finish.

Tip: Double-check thickness before choosing tools. Using the wrong method for your sheet type can lead to chipping or poor alignment.

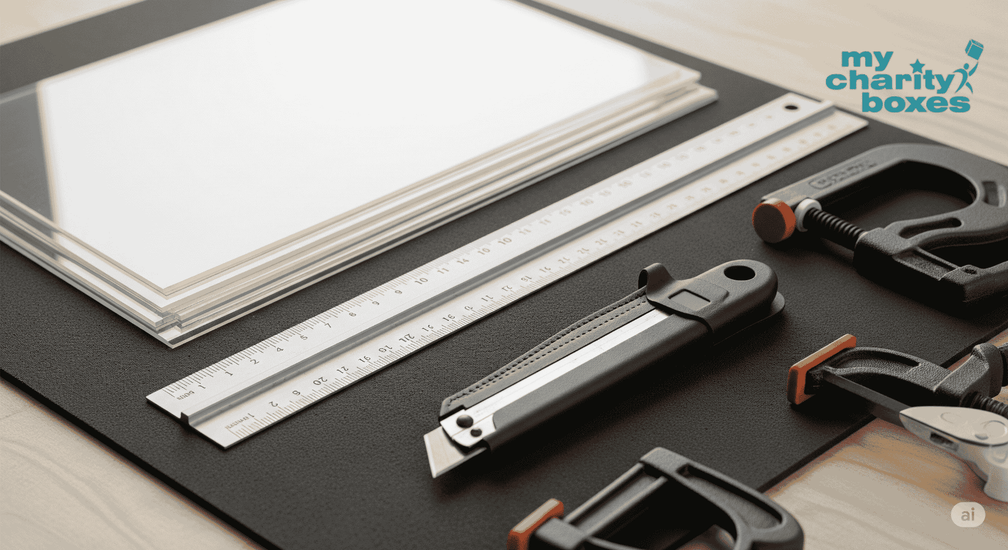

Tools for Cutting Acrylic

Having the right tools can make the difference between a smooth, safe cut and a frustrating project.

Essential Tools by Sheet Thickness

For Thin Sheets (≤ 1/8” / 3mm):

- Acrylic Scoring Knife: Inexpensive and effective. Creates a controlled break line.

- Metal Ruler or Straightedge: Needed to guide your scoring lines.

- Workbench/Table Edge: Required for snapping scored sheets cleanly.

For Thick Sheets (≥ 3/16” / 4.5mm):

- Jigsaw with Fine-Tooth Blade: A slow, controlled way to cut complex shapes or curves.

- Circular Saw with Acrylic Blade: Best for long, straight cuts. Provides speed and precision.

- C-Clamps or Workbench Clamps: Secure your material firmly to avoid shifting.

For Precision and Repetition:

- Laser Cutter: Ideal for detailed logos, curves, and perfectly measured cuts. Found in many makerspaces.

Recommended Safety Gear:

- Cut-Resistant Gloves: Protect your hands from slips or sharp edges.

- Protective Goggles: Guard against flying chips or dust.

- Dust Mask or Respirator: Acrylic particles can be harmful if inhaled during power cutting.

- Hearing Protection: If using power saws, especially indoors.

What NOT to Use:

|

Tool or Method |

Why It’s Unsafe or Ineffective |

|

Dull blades |

Cause uneven edges and increase risk of cracks |

|

Box cutters (for thick sheets) |

Too weak for anything over 1/8"; leads to unsafe pressure |

|

Unventilated heat tools |

Can warp or melt the acrylic unevenly |

|

All-purpose saw blades |

Designed for wood or metal, not plastics; can chip or overheat |

Always check your tools. Using the wrong blade or rushing the process is a common cause of material waste and injury.

Step-by-Step Cutting Instructions

A. Scoring and Snapping Thin Sheets (< 1/8”)

This method is simple, quiet, and doesn’t require power tools. Perfect for small projects.

- Mark your cut line with a pencil or marker.

- Align a metal ruler along the line and press firmly.

- Use a scoring knife to score the acrylic 5–10 times along the ruler.

- Flip the sheet and score the opposite side (optional for cleaner snaps).

- Move the sheet to the edge of your table, with the scored line aligned with the edge.

- Press down firmly on the overhanging section. The sheet should snap cleanly.

Best for: Straight cuts in smaller panels like sign faces or side walls of a box.

B. Cutting Thick Acrylic with a Jigsaw or Circular Saw

Cutting thicker sheets requires more control and power. A slow and steady hand will ensure success.

- Place the acrylic on a stable work surface and secure it with clamps.

- Apply painter’s tape over the cut line to reduce chipping.

- Use a fine-tooth blade made for plastic. (60+ teeth recommended for circular saws.)

- Line up your saw and cut slowly, letting the blade do the work.

- Do not pause mid-cut—this may cause melting or snags.

- Once finished, let the material cool fully before moving.

Note: Cutting too fast can create friction, which may melt the edge.

C. Using a Laser Cutter (Advanced/Professional)

Laser cutting delivers flawless results but requires access to the right equipment. Ideal for complex shapes or bulk production.

- Create or import your design into laser-cutting software.

- Set the correct power and speed settings for your acrylic thickness.

- Do a test cut on a scrap piece.

- Run the full cut—no sanding or polishing needed.

Best for: Logos, stencils, perfect repeatable cuts, or brand-specific projects.

Finishing the Edges

After cutting, acrylic edges can feel sharp or appear rough. Finishing polishes your project—literally.

How to Smooth Acrylic Edges:

- Sand the edge using fine-grit sandpaper (start at 400, finish at 800 or higher).

- For a clearer finish, apply plastic polish (e.g., Novus) with a soft cloth.

- Chamfer or bevel edges with a hand file for comfort and aesthetics.

- For glossy, glass-like edges, advanced users can use a flame polisher.

Learn post-finish care in How to Clean Acrylic Boxes Without Scratching

Safety Tips for Cutting Acrylic

Acrylic may look like glass, but it behaves very differently. Stay safe with these essential tips:

Key Safety Reminders:

- Work in a well-ventilated area. Fumes and dust should not be inhaled.

- Wear safety goggles at all times—shards are sharp and fast.

- Clamp your sheet to prevent movement or kickback.

- Avoid rushing the cut. Fast cuts create heat, which can warp or melt the material.

- Never leave saws running unattended.

Don’t underestimate plastic dust. Clean up with a vacuum or damp cloth—never blow it into the air.

When to Cut vs. When to Buy Pre-Made

DIY is rewarding—but it’s not always practical. Knowing when to build or buy saves time, money, and frustration.

Cutting Yourself Is Ideal If:

- You’re building multiple units for a campaign

- You already own tools or have access to a workshop

- You want full control over sizing and design

- You enjoy DIY challenges and have the time to experiment

Buying Is Smarter If:

- You need a secure, finished product fast

- You don’t have tools or experience

- You want perfect edges, pre-installed locks, or branding

- You’re worried about waste, safety, or precision

Want to build from scratch? Read our DIY Acrylic Donation Box Tutorial

Want to skip the hassle? Shop our acrylic donation boxes for ready-to-use, professionally cut options.

Conclusion

Cutting acrylic sheets doesn’t have to be intimidating. With the right tools, clear steps, and a focus on safety, anyone can master the basics and create beautiful, functional acrylic panels—whether for a donation box, sign, or display.

But remember, not every project has to be DIY. For reliable results, secure designs, and polished finishes, My Charity Boxes offers high-quality acrylic donation boxes shipped ready to use.

Ready to try your own build?

Check out our tutorials and tool tips. Prefer a hands-off approach? Browse our shop for custom, bulk, and lockable options.

Need help picking acrylic sheets or dimensions? Contact us for friendly, expert advice.

FAQs

What’s the best way to cut acrylic without cracking it?

For thin sheets, use a scoring knife and snap along a straight edge. For thick sheets, use a circular saw with a fine-tooth blade, cutting slowly.

Can I use a box cutter to cut acrylic?

Only for sheets thinner than 1/8" (3mm). For thicker sheets, use a jigsaw or circular saw.

Do I need a laser cutter for clean edges?

No. While a laser cutter gives precise results, you can achieve smooth edges manually with sanding and polishing.